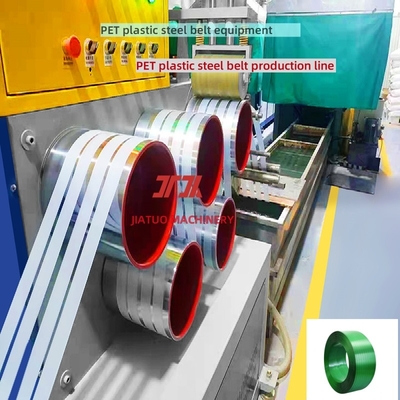

100% 분쇄 된 재료 PET 플라스틱 철강 벨트 생산 라인 고속 PET 벨트 제조 기계

제품 설명 PET STRAPPINE 기계

PET plastic-steel strapping equipment is a specialized production line that converts recycled or virgin polyethylene terephthalate (PET) into high-strength plastic strapping through a process including melting, 진압, 스트레칭, 모양, 와일링. PET 플라스틱-강 스트랩은 철강, 알루미늄, 종이 제조, 화학 섬유,그리고 높은 강도 때문에 건축물, 부식 저항성, 미적 매력, 재활용성

특징

1튼튼한 견고성PET 스트랩 테이프 생산 라인은 철강 테이프의 팽창 강도, 좋은 유연성, 좋은 충격 저항성을 가지고 있으며 깨지기 쉽지 않으며 제품 운송의 안전을 보장합니다.

2작은 연장--PET 스트랩 테이프는 플라스틱의 일종이지만, 그 길이는 거의 변하지 않으며, 그 길이는 폴리프로필렌의 1/6에 불과합니다.그것은 긴장을 유지하고 포장 후 확장 및 수축 양이 더 이상 변경되지 않도록 할 수 있습니다.

3강한 온도 저항력 --실험에 따르면 PET 스트랩 테이프의 녹는점은 약 260°C이며 120°C에서 변형없이 오랫동안 사용할 수 있으며 안정성이 좋습니다.

4좋은 경제적 이득--PET 스트랩 테이프의 밀도는 1.30~1.38g/cm3이며, 이것은 철강 테이프의 밀도의 1/6 (7.8g/cm3) 에 불과하며, 이는 6톤의 철강 테이프의 길이에 해당합니다.그리고 단위 길이당 가격은 상대적으로 낮습니다..

추출 매개 변수 표

| 모델 |

PET-2 |

PET-3 |

PET-4 |

PET-6 |

PET-8 |

| 원자재 |

병 flakes/crushed materials 병 flakes/crushed materials) 또는 분쇄된 재료 |

| 테이프 수 |

2 |

3 |

4 |

6 |

8 |

| 너비 (mm) |

9-32 |

| 두께 (mm) |

0.4-12 |

| 최대 선속도 (m/min) |

¥150 |

¥150 |

¥150 |

¥150 |

¥150 |

| 스크루 모델 |

90 |

100 |

125 |

150 |

180 |

| 환전기 모델 |

200 |

250 |

280 |

315 |

350 |

| 비습기 |

1000 |

1000 |

2000 |

3000 |

3500 |

| 측정 펌프 |

100cc |

| 생산 용량 /24 H |

5-6T |

7-8T |

10-12T |

12-15T |

18-20T |

PET 포장 벨트 생산 라인 프로세스 흐름

① feeding→② mixing raw materials→③ raw material pre-drying→④ vacuum dehumidification of raw materials→⑤ raw materials melting extrusion→⑥ material embryo expression(with embryo) cooling molding→⑦oven preheating→⑧first stretching→⑨second stretching→⑩embossing→⑪ oven tempering to set the shape→⑫ cooling → ⑬winding(finished product)

원자재---

100% PET 분쇄물질 또는 병 flakes

PET 플라스틱 철강 벨트 생산 장비를 구입할 때 무엇에주의를 기울여야합니까?

PET 플라스틱 철강 벨트 생산 장비를 구매할 때 다음 사항은 고려해야 합니다.

생산 필요, 장비 성능, 공급자 강도, 기술 서비스 및 기타 측면을 포괄적으로 고려하여 장비의 적응성을 보장합니다.비용 효율성 및 생산 안정성.

1생산 필요와 위치

용량 계획

장비 모델, 진압 출력 등을 선택합니다.120~200m/min 이상) 및 예상 출력에 따라 연속 작동 능력으로 생산 용량이 부족하거나 과도한 투자가 방지됩니다..

원자재 종류

PET 플라스틱 철강 벨트 생산 장비에 사용할 수 있는 원료를 결정합니다.

100% 새로운 PET 분쇄물질 또는 재활용된 분쇄물질

제품 사양 및 기능 요구 사항

스펙트럼------ 너비 (9mm-32mm), 두께 (0.6mm-1.2mm), 팽창 강도 (≥1800N 등) 및 기타 매개 변수, 장비는 유연한 조절을 지원해야 합니다.

함수------ 웅진 (상승 마찰), 색상 인쇄, 맞춤 팽창 강도 등이 필요한지,일부 장비는 부각 롤러 또는 마스터배치 추가 시스템으로 추가적으로 장착되어야합니다..

2- 장비의 핵심 성능과 기술적 매개 변수에 주의를 기울여

호스트 및 추출 시스템

나사 설계: 원재료가 완전히 녹아내리고 불량 플라스틱화 (구구멍과 부러진 벨트) 를 줄이기 위해 큰 비율 (30:1) 을 가진 나사를 선호합니다.

난방 시스템------ 소재의 지역 과열 및 분해를 피하기 위해 세라믹 난방 고리, 고온 및 고전력 난방 튜브 및 나사의 균일 난방을 사용하십시오.

진압 부피 안정성 ---- 100CC 측정 용액 펌프로 장착압력 센서와 자동 조절 장치로 안정적인 진압 속도를 보장하고 완성된 PP 벨트의 너비와 두께의 변동을 피합니다..

스트레칭 및 형성 시스템

팽창 복수---PET 플라스틱 강철 벨트는 강도를 높이기 위해 팽창해야합니다. 팽창 복수는 일반적으로 3-10 배입니다.장비가 정확한 제어 기능을 지원해야 합니다 (예를 들어, 80-100°C의 1차 스트레칭 온도와 120-150°C의 2차 스트레칭 온도);

모양을 만드는 방법: 물 냉각 또는 공기 냉각 시스템은 PET 벨트의 변형을 방지하고 윙의 평평성에 영향을 미치기 위해 균일해야합니다.

자동화 및 제어 시스템

지능: PLC 제어 시스템 + 터치 스크린 조작 인터페이스를 선택하고 매개 변수 (온도, 압력, 견인 속도 등) 및 고장 경보를 실시간 모니터링 할 수 있습니다.

에너지 절약 및 환경 보호 설계

에너지 절감 ---- 세르보 모터 또는 에너지 절감 모터를 사용하여 일반 모터에 비해 30% 이상의 전력을 절약합니다.

생산 ---- 기계의 고속 작동, 생산을 40-50% 이상 증가

간단한 작업-- 1-2명을 줄여라.

.

FAQ:

Q: PET 플라스틱 강철 벨트 장비의 전압은 무엇입니까?

A: 380V/50HZ, 3단계 (개인화 지원)

Q: PET 플라스틱 강철 벨트 장비의 진압 용량은 무엇입니까?

A: 각기 다른 모델은 150-600KG/h의 용량을 가진 각기 다른 진압 용량을 가지고 있습니다.

Q: PET 플라스틱 강철 벨트 장비의 생산 가능한 폭은 무엇입니까?

A: 9~32mm

Q: PET 플라스틱 철강 벨트 장비는 사용자 정의 될 수 있습니까?

A: 사용자 정의 지원

Q: PET 플라스틱 철강 벨트 장비는 어디서 왔나요?

A: 중국.

Q: PET 플라스틱 강철 벨트 장비의 인증은 무엇입니까?

A: ISO CEO 자격증

Q: PET 플라스틱 강철 벨트 장비의 최소 주문 양은 무엇입니까?

A: 1 세트

Q: PET 플라스틱 강철 벨트 장비의 무게는 무엇입니까?

20T, 40GP 컨테이너 * 3PCS

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!

전체 등급

등급 스냅샷

다음은 모든 평점의 분포입니다.모든 리뷰